Precision Engineering: Inside Gas Turbine Components

- bvlturbineparts

- Mar 6, 2024

- 2 min read

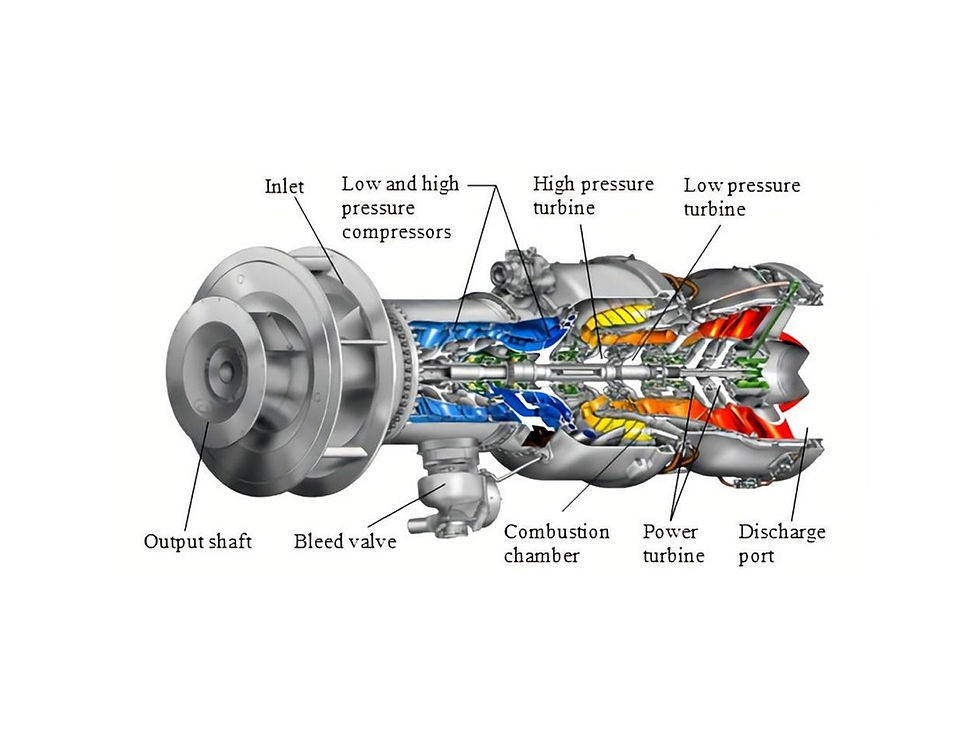

Gas turbine components are the backbone of power generation and propulsion systems, renowned for their efficiency, reliability, and precision engineering. As integral parts of turbines, these components undergo rigorous design, manufacturing, and testing processes to ensure optimal performance and durability. In this article, we delve into the world of gas turbine components, exploring their intricate design, manufacturing techniques, and the role they play in powering various industries.

Introduction to Gas Turbine Components

Gas turbines are widely used in power plants, aircraft propulsion, and other industrial applications due to their ability to efficiently convert fuel into mechanical energy. At the heart of these turbines lie various components, each meticulously engineered to withstand high temperatures, pressures, and rotational speeds. From compressor blades and combustion chambers to turbine rotors and nozzles, every component plays a crucial role in the turbine's operation.

Precision Engineering at BVPL Turbine Parts

At BVPL Turbine Parts, we specialize in the design and manufacturing of high-quality gas turbine components for a wide range of applications. Our team of engineers and technicians are dedicated to delivering precision-engineered solutions that meet the demanding requirements of our clients. Through advanced machining techniques, state-of-the-art materials, and stringent quality control measures, we ensure that each component meets the highest standards of performance and reliability.

Design and Development Process

The design and development of gas turbine components involve a multidisciplinary approach, combining expertise in mechanical engineering, materials science, aerodynamics, and thermal dynamics. At BVPL Turbine Parts, our engineers utilize cutting-edge software tools and simulation techniques to optimize the performance and efficiency of each component. From initial concept and design validation to prototype testing and final production, every step of the process is meticulously planned and executed to ensure the highest quality standards.

Manufacturing Techniques

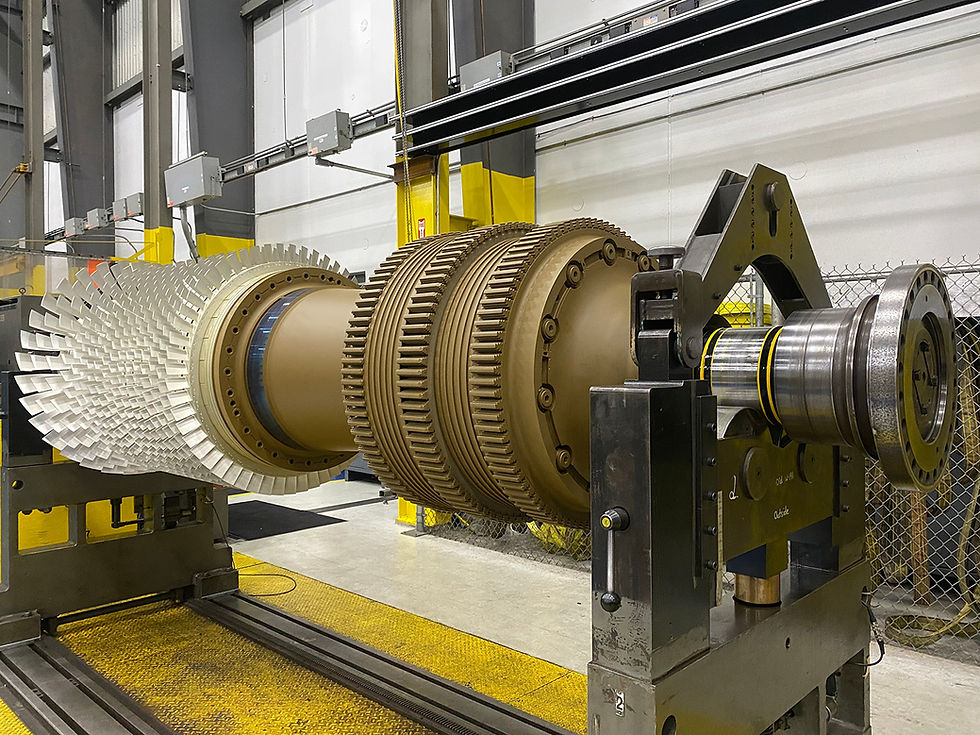

Precision manufacturing is crucial in producing gas turbine components that meet the tight tolerances and exact specifications required for reliable operation. At BVPL Turbine Parts, we leverage a combination of advanced machining technologies, such as CNC milling, turning, and grinding, to produce components with exceptional accuracy and surface finish. Additionally, we utilize specialized heat treatment processes to enhance the mechanical properties and durability of critical components subjected to high temperatures and stress.

Quality Assurance

Quality assurance is paramount in the aerospace and power generation industries, where safety and reliability are of utmost importance. At BVPL Turbine Parts, we adhere to stringent quality control procedures throughout the manufacturing process to ensure that each component meets the highest standards of performance and reliability. From raw material inspection and dimensional checks to non-destructive testing and final inspection, every component undergoes rigorous scrutiny to detect any defects or deviations from specifications.

Conclusion

Gas turbine components are marvels of precision engineering, essential for powering a wide range of industrial and aerospace applications. At BVPL Turbine Parts, we are committed to delivering high-quality components that meet the demanding requirements of our clients worldwide. Through our dedication to precision engineering, advanced manufacturing techniques, and stringent quality control measures, we continue to push the boundaries of innovation in gas turbine component technology.

Comments